Tel :18138443506

Phone :13798439478

Email :mammon.xu@zhixin-cert.com

Addr :Floor 3, No. 5, Shanglian New Village, Shangcun Community, Gongming Street, Guangming District, Shenzhen (Chuangxin Office Building)

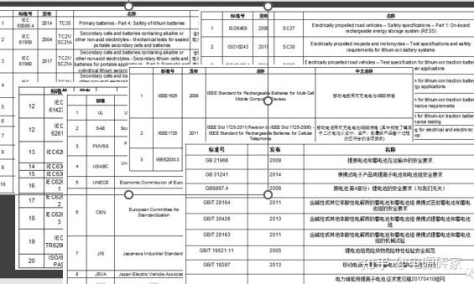

一、Battery test standard

It can be seen from the statistical table that the formulation or revision of lithium ion battery standards in China is very active, which is also the need for the market to constantly improve the safety performance of lithium ion batteries. On the other hand, it also brings more severe challenges to battery manufacturers, requiring them to constantly improve their level in the design, production and testing process.

At present, the common test standards for lithium batteries are

At present, the common test standards for lithium batteries are

•GB/T 18287

•IEC 61960

•IEC 60086-4

•IEC 62133

•JIS C 8714

•UL 1642

•UL 2054

2、 Taking electrical performance test as an example, common tests

Battery capacity test

1. Battery capacity

The total battery capacity is expressed in C. The battery capacity is generally expressed in mAh milliampere hour, and the capacity of 1mAh battery is expressed in 1 milliampere constant current for 1 hour.

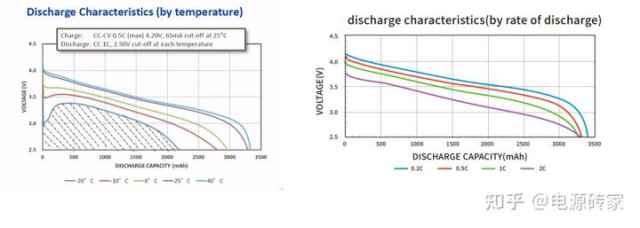

Battery discharge curve at different temperatures and at different discharge rates

The capacity test needs to use the static capacity test method (SCT) to measure the battery usable capacity (including energy) at different ambient temperatures Different enterprises and standards have differences in SCT testing methods, but the general idea is similar For example: fully charge the battery in the way specified by the battery manufacturer under normal temperature (25 ℃), and then discharge to the cut-off voltage (2.5V) at a rate of 1C after fully shelving in the tested environment, and record the released capacity (energy) In the actual experiment, the average value can be taken for three consecutive repeated tests to improve the accuracy Capacity test output: the relationship between temperature and capacity (energy) Take capacity C as the X axis and voltage V as the Y axis The point of 1C discharge cutoff on the X axis at different temperatures is the relationship between capacity and temperature.

HPPC test

The HPPC (Hybrid Pulse Power Characterization) test aims to determine the dynamic power capability of the battery pack under current pulse conditions, including the battery pack's 10 second charge power and 10 second discharge power.

Other tests

Equalizing charge and discharge test

Dynamic condition simulation test

Equalizing charge and discharge test

Battery temperature test

Self discharge

Battery test system functions:

1 Energy feedback test system

2. Constant current, constant pressure, constant flow, constant pressure, slope, ladder, etc

3 Internal resistance test

4 Battery temperature monitoring

5 Battery cycle charge and discharge test

6 Battery capacity test

6. Battery overcharge and overdischarge rate tolerance test

7 Test on charge holding capacity of power battery

8 Battery performance test at different temperatures, including charge discharge performance test and efficiency test

9 High speed current pulse test

10. Battery cycle condition test

Service Hotline

18138443506

13798439478